When you start to assemble, you must need a stencil to help you.

- Author:Admin

- Time:2023-06-08

- Browse:

When you start to assemble, you must need a stencil to help you.

What is a stencil?

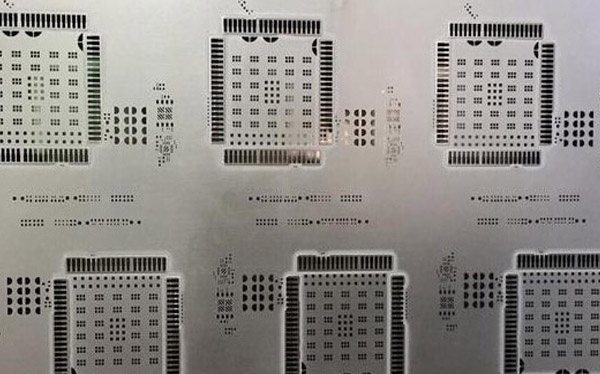

Stencils, also known as SMT Stencil, is a special mold for SMT. Its main function is to aid in the deposition of solder paste; the purpose is to transfer the exact amount of solder paste to the exact location on the empty PCB.

The manufacturing process of SMT steel mesh can be divided into a laser template, electropolishing template, electroforming template, step template, bonding template, nickel plating template, and etching template.

The production process of the stencil includes chemical etching, laser cutting, and electroform.

MARK point: an optical positioning point designed for accurate alignment between the steel mesh and PCB during printing

There are mainly the following factors that will affect the quality of steel mesh:

1. Manufacturing process

We discussed the manufacturing process of steel mesh earlier, we can know that the best process should be electropolishing after laser cutting. Both chemical etching and electroforming have processes such as filmmaking, exposure, and development that are prone to errors, and electroforming is also affected by uneven substrates.

2. Materials used

Including screen frame, wire mesh, steel sheet, adhesive glue, etc. The screen frame must be able to withstand a certain program of relay and have good levelness; it is best to use polyester mesh for the wire mesh, which can maintain stable tension for a long time; it is best to use 304 for the steel sheet, and the matte one is better than the mirror one. It is more conducive to the rolling of solder paste (glue); the adhesive must be strong enough and resistant to certain corrosion.

3. Opening design

The quality of the opening design has the greatest impact on the quality of the steel mesh. As discussed above, the design of the opening should consider the manufacturing process, aspect ratio, area ratio, experience value, etc.

4. Production materials

Whether the production materials are complete or not will also affect the quality of the stencil. The more complete the information, the better. At the same time, when data coexist, it should be clear which one prevails. Also, generally speaking, making stencils with data files can reduce errors as much as possible.

5. How to use

The correct printing method can maintain the quality of the stencil. On the contrary, incorrect printing methods such as excessive pressure, uneven printing of the stencil or PCB, etc., will damage the stencil.

6. Cleaning

Solder paste (adhesive) is relatively easy to cure, if not cleaned in time, it will block the opening of the stencil, and the next printing will be difficult. Therefore, after the stencil is removed from the machine or the solder paste is not printed on the printing machine for 1 hour, it should be cleaned in time.

7. Storage

The stencil should be stored in a specific storage place, and should not be randomly placed, so as to avoid accidental damage to the stencil. At the same time, the stencils should not be stacked together, which is not easy to handle and may bend the screen frame.

Disclaimer: All works (images, text, audio, and video) on this website are compiled from internet sources for the purpose of learning and communication among users. If your rights have been infringed, please contact the administrator to request removal.

URL:http://www.worthpcb.com/index.php?c=article&id=191

Recommend Article

- What is a four-layer pcb?

- What is double-layer PCB?

- We often encounter special process problems d...

- When you start to assemble, you must need a s...

- Professional Surface-mounting and Through-hol...

- Multilayer PCB provide higher design flexibil...

- HDI PCB is typically made using the following...

- What is HDI PCB?

- Why is FR4 prioritized as the PCB base materi...

- Professional Custom PCB and PCBA manufacturer...

- High-Quality PCB Manufacturer Multi-layer PCB

- Customized FR4 Double Layer PCB