HDI PCB is typically made using the following raw materials:

- Author:Admin

- Time:2023-06-08

- Browse:

HDI PCB is typically made using the following raw materials:

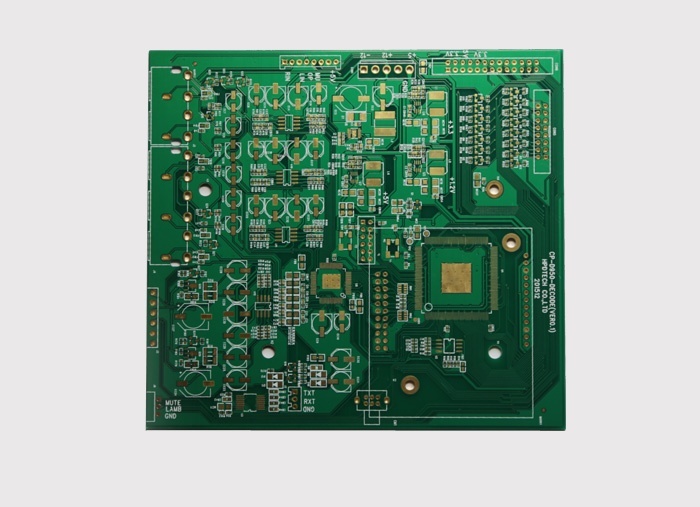

Substrate Material: The substrate material used in HDI PCB is typically a high-quality laminate or resin material. Commonly used substrate materials include FR-4 (Flame Retardant 4), which is a fiberglass-reinforced epoxy laminate, or other specialized high-performance materials such as polyimide (PI) or liquid crystal polymer (LCP).

Copper Foil: Copper foil is used to create conductive layers and traces on the PCB. It is typically laminated onto the substrate material using an adhesive.

Prepreg: Prepreg is a resin-impregnated fiberglass material used to bond the layers of the PCB together. It helps provide mechanical strength and insulation between the layers.

Solder Mask: The solder mask is a protective layer applied to the surface of the PCB to protect the copper traces from oxidation, contamination, and short circuits. It is typically made of epoxy-based or liquid photo imageable solder mask (LPSM) materials.

Surface Finish: The surface finish is a final coating applied to the exposed copper traces and pads to protect them from oxidation and facilitate soldering. Common surface finish options for HDI PCB include electroless nickel immersion gold (ENIG), immersion silver, or organic solderability preservatives (OSP).

These materials are carefully selected based on the specific requirements of the HDI PCB design, such as electrical performance, thermal management, and reliability.

Disclaimer: All works (images, text, audio, and video) on this website are compiled from internet sources for the purpose of learning and communication among users. If your rights have been infringed, please contact the administrator to request removal.

URL:http://www.worthpcb.com/index.php?c=article&id=188

Recommend Article

- What is a four-layer pcb?

- What is double-layer PCB?

- We often encounter special process problems d...

- When you start to assemble, you must need a s...

- Professional Surface-mounting and Through-hol...

- Multilayer PCB provide higher design flexibil...

- HDI PCB is typically made using the following...

- What is HDI PCB?

- Why is FR4 prioritized as the PCB base materi...

- Professional Custom PCB and PCBA manufacturer...

- High-Quality PCB Manufacturer Multi-layer PCB

- Customized FR4 Double Layer PCB